2013 ENVE Composites DH Wheels Review ENVE is proud to release the world’s first all carbon downhill rim .It is most likely truthful to mention that ENVE’s carbon rims area unit handily a number of the foremost lusted once parts that may be intercalary to a motorbike. sort of a recent combine of Air Jordans, these trick hoops instantly elevate any rider to ‘baller’ standing. Even riders United Nations agency are not conversant in these wheels can stop and raise, “Are those carbon rims?” All this attention is well-deserved once distributing $2,888 USD for set of complete wheels a twin of what is tested here, to not mention the rim-only value of $999 USD. there is no denying it – that is a hell of plenty of cash, particularly considering the very fact that one will assemble a awfully tight wheelset for the value of one 475 gram ENVE rim. Given their high value, what precisely area unit you obtaining once parting ways in which with all those hard-earned dollars?

ENVE DH Wheelset Details • Purpose: Downhill |

While the initial sticker shock may cause heart palpitations, the exotic combo of ENVE’s carbon rims laced to Chris King hubs are the pinnacle of downhill wheel design and technology. The ENVE Difference

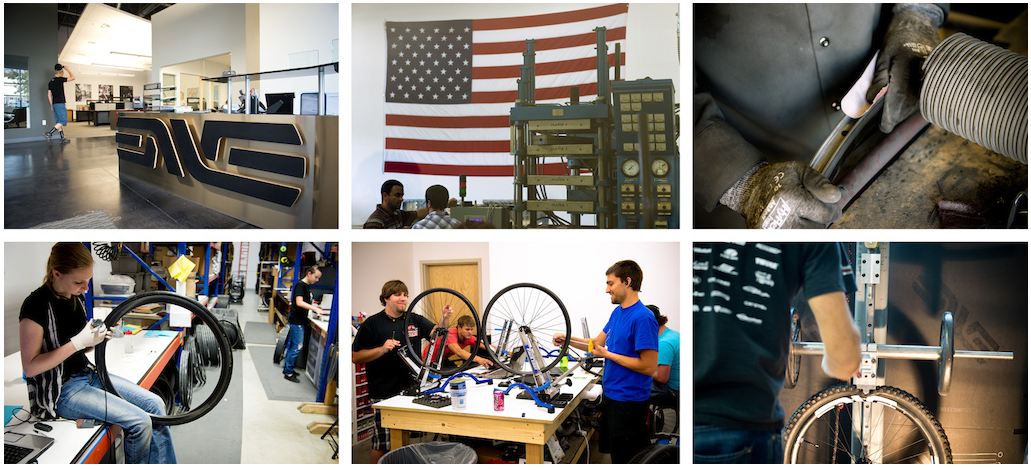

Employing a patented and proprietary process for their carbon rim production, ENVE is confident their DH rim is up to the task of downhill riding and racing. Utilizing state of the art carbon production techniques, ENVE is able to create a rim that is not only lighter than most every rim intended for the same use, but one they claim is stiffer, stronger, and more resilient than any other comparable rim. To create the hollow rim internals, an inflatable bladder is incorporated into the carbon layup. ENVE’s proprietary carbon layup process utilizes an inflated bladder that is removed after molding. The rim is then patched and refinished. Alloy spoke nipples are located inside the rim and require a specific spoke wrench for building/tensioning/truing.

Wheel Stiffness

Spoke tension is also unusually high, with ENVE going beyond the upper limits of what would typically be seen on an aluminum-rimmed, 32-spoke wheel build. Traditional wheel builds registering 1,000 Newtons of spoke deflection are considered to be at the upper limit of spoke tension, but our test wheels meter in at 1,200-1,300 Newtons. Rather than drilling the spoke nipple holes through the rim wall, ENVE’s uni-directional carbon fiber strands are routed around the spoke holes and continue around the molded rim. Handmade in USA is only part of the cost of these rims. In-house Testing

Rims and wheels from every manufacturer are tested with the same variables against ENVE’s own carbon rims to establish their production standards. As seen below, ENVE tests how a competitor’s rim holds up against their own in the square-edge test. Riding ENVE’s Carbon DH Wheels

We’ve ridden a lot of different wheelsets in our time, but never before has one felt so obviously different than the carbon-rimmed ENVE set. ENVE’s stiff wheels simply transfer energy better. Stiff wheels inspire confidence in all situations.

One of the best qualities of using carbon for a rim material is that it can be configured to resist impact damage much better than an alloy rim. This impact resistance allows riders to run lower air pressure without worrying about flat spotting or denting the rim’s sidewalls. Our rear carbon rim couldn’t handle a big G-out in uneven bedrock. It goes without saying that a rim of any material should be replaced after this, but purely out of curiosity we decided to continue riding on the ENVE rim. ENVE had this to say about our damaged rim:

The rims initially delivered for testing were from a batch of lighter weight pre-production prototypes developed for smoother World Cup courses and lighter weight racers. It is of note that the rim returned to ENVE exhibited no damage to the actual hook bead and tire bed of the rim. ENVE replaced the test rims with current production rims that are 30 grams per rim heavier than the version reviewed here.

WimBike Take :

The wheelset’s unimaginable rigidity adds up to very good cornering and acceleration talents, creating them ideal for a racer UN agency is searching for that flash advantage on race day, however we’ve got to admit that we might like better to highly to|favor to|opt to|choose to} ride a more ancient wheelset for day to day use. And whereas we tend to actually respect and appreciate domestic producing, the first crack that we tend to practised proves that carbon reliableness usually boils right down to the human bit in spite of that country the element is created in. Would we’ve got had years of untroubled use if we tend to merely replaced the broken rim by method of ENVE’s 5-year warranty? probably, once more} again we all know with close to certainty that any client UN agency obtained these wheels with their hard-earned cash would feel quite disappointed by the failure within the initial place. the $64000 edges of ENVE’s DH wheelset comes from supplementary stiffness, flat-spot resilience, and a few attainable weight savings. None of this can relate the typical rider, once more} again, this is not your average product. Those searching for the competitive edge simply may even see the worth. -Brad Walton

Source and Image Credit: © pinkbike